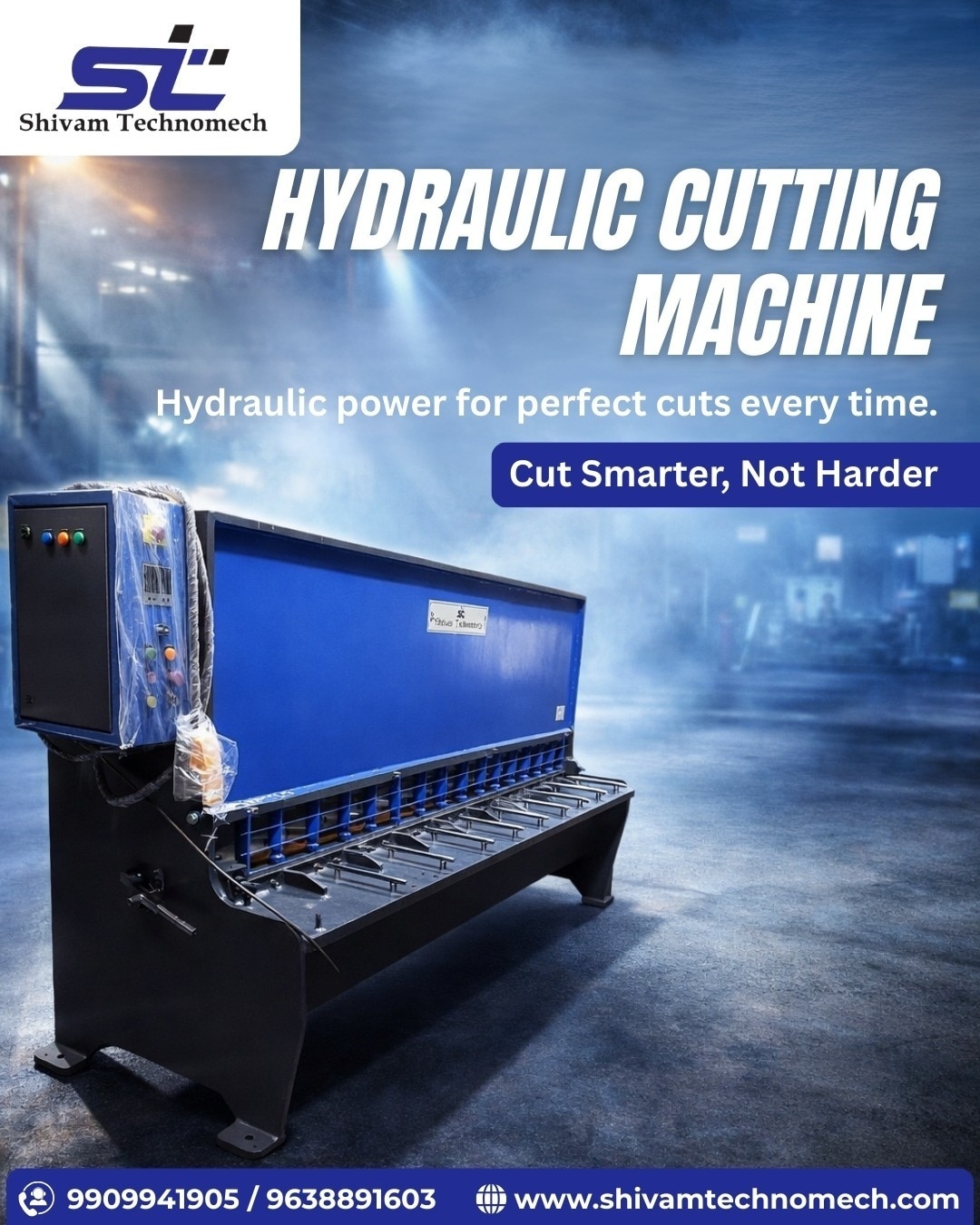

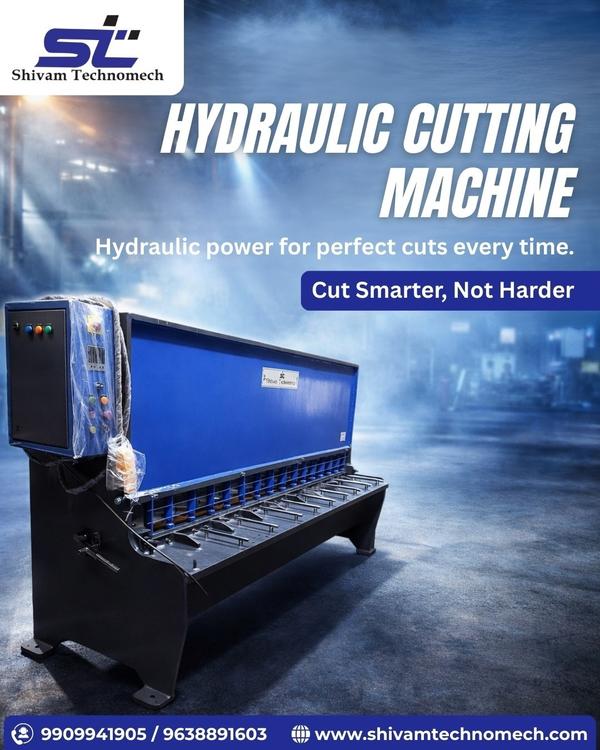

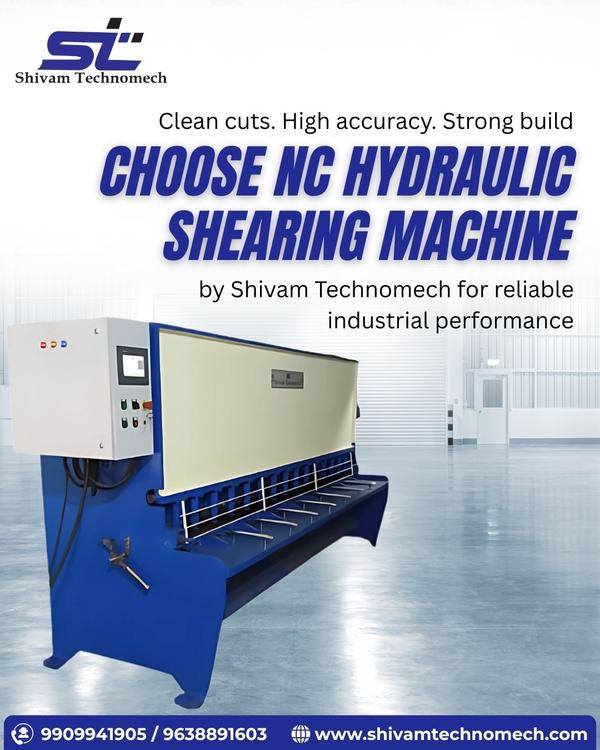

Hydraulic Shearing Machine Manufacturer in India. Looking for a trusted Hydraulic Shearing Machine Manufacturer in India? We specialize in high-performance Sheet Metal Cutting Machines designed for precision, power, and durability. Our models offer maximum shearing up to 2500 mm and 4000 mm, with advanced foot brake shearing and plate bending options. Built with a rugged structure, synchronized moving beam, and hydraulic clamping system, our shearing machines ensure smooth, accurate, and twist-free cuts every time. Ideal for heavy-duty metal fabrication, automotive, and industrial sheet cutting applications. Experience superior performance, low noise operation, and reliable efficiency. Contact us for NC Hydraulic Shearing Machine solutions today.

About SHIVAM TECHNOMECH

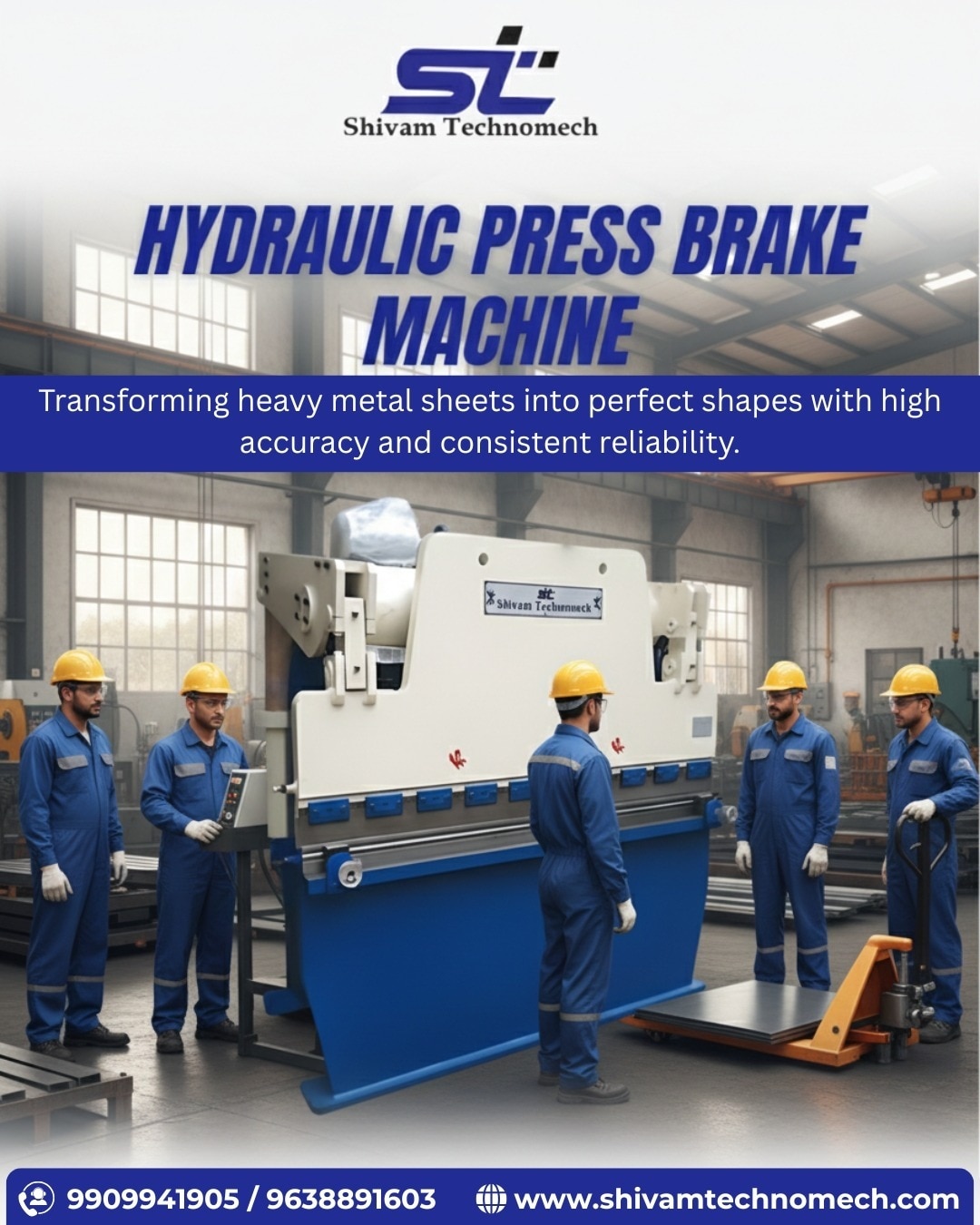

The Best Hydraulic Press Brake Machine Manufacturer in ahmedabad

Products

Featured ProductsWhat We Do

Have any custom requirements?

Testimonials

View All

Ketan Joshi

Big projects used to stress us out, but this press brake makes bending easier and consistent. Totally reliable.

Vikram Shah, Metal Fabrication

Hume accurate bending chahiye thi, aur yeh machine perfectly kaam kar rahi hai. Quality se bahut khush hain.

Anjali Desai, Elevator Manufacturing

I was a bit worried about switching machines, but this one is spot-on. Bends are precise, and the support team answers e...

Read More

×

![]()